|

|

Stephen Eakins and Creag Louttit's THRUST SSM

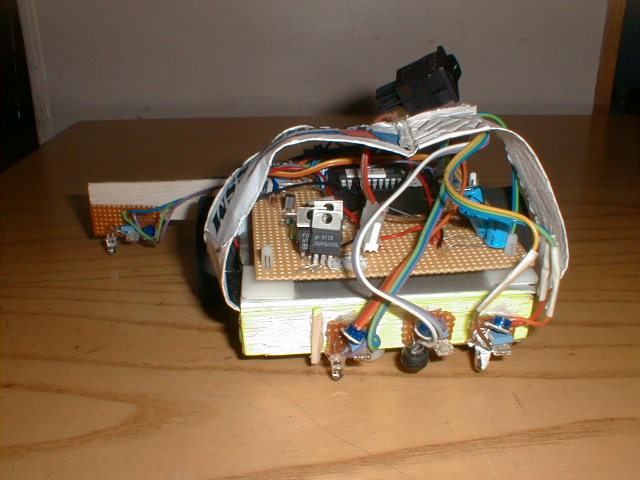

This is a sophisticated mouse that bears little resemblance to a DASH FREE. It uses an Atmel AVR 1200 microcontroller for control and four Hamamatsu S4282-11 sensors. The motors are our E400s and the gearboxes are built from our M217 gear sets. It has two batteries; a small 4.8V NiCd stack for the processor and sensors and 4 AA NiCds for the motors.

The motors are PWM controlled from the AVR with armature-voltage speed feedback. The processor can apply braking via power FETs shunting the motors.

THRUST has three sensors at the front for sensing its position relative to the tape line. The fourth sensor at the back is used to detect the timing bars as they go past. THRUST "knows" where it is on the circuit and adjusts its speed accordingly.

THRUST has wide wheels taken from a radio control car. The foam rubber tyres give excellent traction and skid resistance. The third support is a nylon dome nut for minimum friction. The chassis is a piece of bent aluminium and the gearboxes are made with two sheets of plastic as bearing plates.

Work on THRUST started in September 1997 and it only ran its first lap 5 days before the competition! There are several different program chips that can be fitted to give different levels of performance and reliability. Only the slowest one was used at Manchester as this was sufficient given the opposition encountered.

The fastest chip currently developed uses the timing bar sensor to work out where it is on the lap. It starts at a corner and runs 4 timing bars "flat out", slows down for the next timing bar and then turns the corner. It then runs one timing bar in "slow" mode before the next corner. After that corner it repeats the cycle.

The "slow" chip used at Manchester ran 6.5 seconds and was only mildly unreliable!

There is a great deal of development potential for THRUST. The design equations were based on an average speed of 1 metre/second to get a lap time of 3.25 seconds. This is the target the team is aiming at but there is a lot of difference between what you can achieve on a spreadsheet simulation and what you get when you try things out on the track!

One area that still has to be tackled is the problem of the super-standard class. To compete effectively in this THRUST will need to do a slow lap to learn where all the corners are and then it will be able to use its timing bar sensing system to put in a really fast lap. The AVR1200 may not have the resources to do this but there are pin-compatible members of the family that have.

The real limitation on the performance of mice of this type is the amount of time available for program development. AVRs, PICs etc. can only practicably be programmed in assembler for this type of application and the learning time plus the development time is a problem for most 12 to 16 year-olds. Fortunately Creag and Steve will still meet the age criteria for another couple of years so they should have time to improve THRUST significantly.

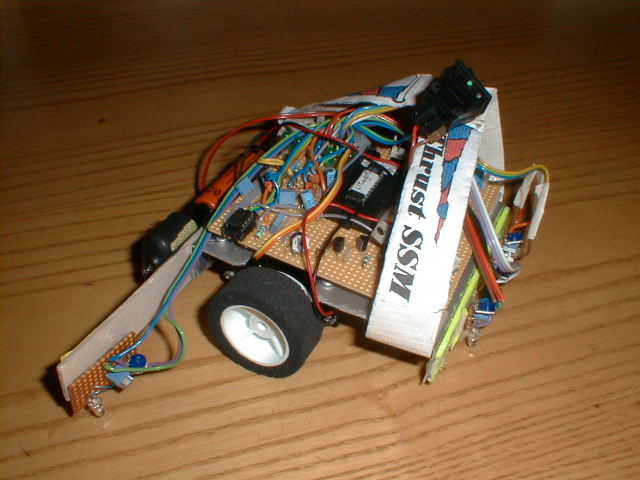

This photo shows THRUST running in the final at Manchester. Creag's grin shows that they had already won when this was taken!

HOME PAGE

HOME PAGE PIXIE

PIXIE DASH FREE

DASH FREE