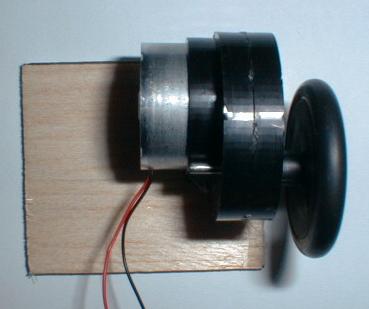

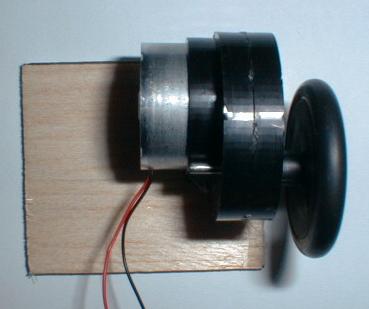

The chassis is made out of balsa wood and hot melt glue. The top chassis plate is made out of 2.5 mm thick balsa wood. It is 50 mm by 45 mm with the grain running parallel to the 50 mm side. I used a scalpel to cut the balsa wood.

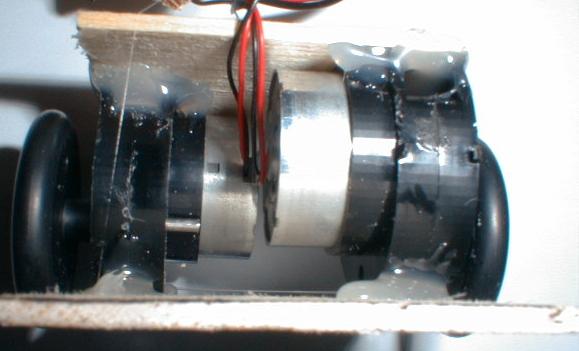

The drive train assemblies are attached to the top chassis plate with hot melt glue. Be careful not to get glue on the wheels or your fingers!

Fit one side and leave it to cool down. I tacked it with small amounts of glue and when that had cooled I came back to it a couple of times to build up the thickness of glue. It takes a while for the glue to cool down so this process could easily take 20 minutes or so for one side.

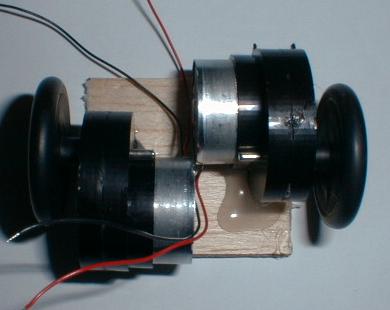

The other side must be carefully lined up. The drive shafts MUST be in line or you will build a bias into the chassis.

When both drive trains are fitted leave it for at least 30 minutes to harden.

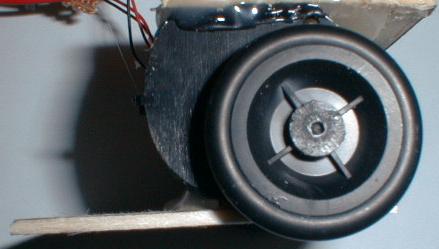

The bottom chassis plate is 50 mm by 60 mm. The grain runs parallel to the long side.

The bottom plate runs forward from just behind the gearbox. You can just see where the back of the plate is behind the wheel. The grain runs from the front to the back. It is held to the gearboxes with hot melt glue.

After the glue has had plenty of time to go hard, fit a slider to the centre front of the bottom chassis plate.

I used a drawing pin. Anything that slides easily and is part of a sphere is good. You could try a nylon dome nut or you could make a posh slider out of PTFE for the lowest friction.